DIN338 Vollgeschliffen HSS M2 Spiralbuer

Fonctiounen

Den DIN338 voll geschliffenen HSS M2 Spiralbuer huet e puer aussergewéinlech Eegeschaften, dorënner:

Héichgeschwindegkeetsstahl (HSS) M2 Material: D'Benotzung vum HSS M2 Material bitt eng iwwerleeën Häert, Verschleißbeständegkeet an Hëtztbeständegkeet, wouduerch dës Buerbits fir d'Buerung vun enger Vielfalt vu Materialien, dorënner Edelstol, Legierungsstahl a schwaarze Metaller, gëeegent sinn.

VOLLSTÄNNEG GESCHLËFFEN NIEWEN A SCHNEIDEKANTEN: De Buer ass präzis geschliffen fir schaarf a konsequent Nuten a Schnéid ze bidden, wat zu enger verbesserter Spanentsuergung, reduzéierter Reibung an erhéichter Buergenauegkeet féiert.

135-Grad-Splitpunkt: De Buer huet en 135-Grad-Splitpunkt-Design, wat hëlleft de Besoin fir Virlächer ze reduzéieren, d'Zentréierungs- a Selbstzentréierungsfäegkeeten ze verbesseren an d'Buereffizienz ze verbesseren.

GLANZEND FINISH: Déi hell Uewerfläch vum Buer widdersteet Korrosioun, fërdert de Spanoflaf a bitt eng verbessert Siichtbarkeet während dem Betrib, wat d'Leeschtung an d'Liewensdauer verbessert.

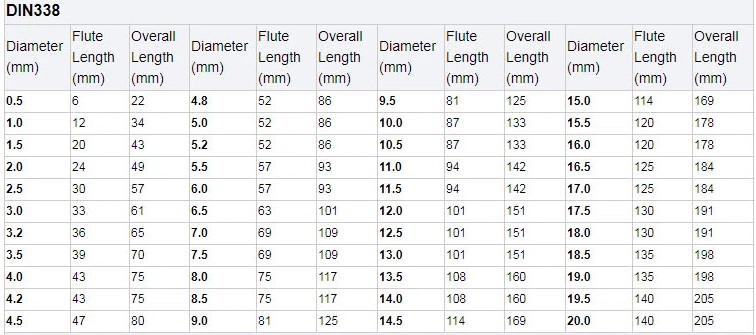

DIN338-konform: Buerer entspriechen den DIN338-Normen, wat konsequent Dimensiounen, héichqualitativ Fabrikatioun a Respekt vun den Industriestandarden fir Genauegkeet a Zouverlässegkeet garantéiert.

Villfälteg Uwendungen: Dës Spiralbuerer si gëeegent fir allgemeng Bueraufgaben a verschiddene Materialien, wouduerch se villfälteg a praktesch fir eng Villfalt vun Buerapplikatioune sinn.

Laang Liewensdauer vum Werkzeug: D'Kombinatioun aus héichwäertege HSS M2 Materialien, Präzisiounsschleifen an engem haltbarem Design hëlleft d'Liewensdauer vum Werkzeug ze verlängeren an d'Ersatz- a Wartungsfrequenz ze reduzéieren.

Zesumme maachen dës Eegeschafte den DIN338 vollgeschliffenen HSS M2 Spiralbuer zu engem zouverléissegen an héichperformanten Tool fir professionell an industriell Buerapplikatiounen.

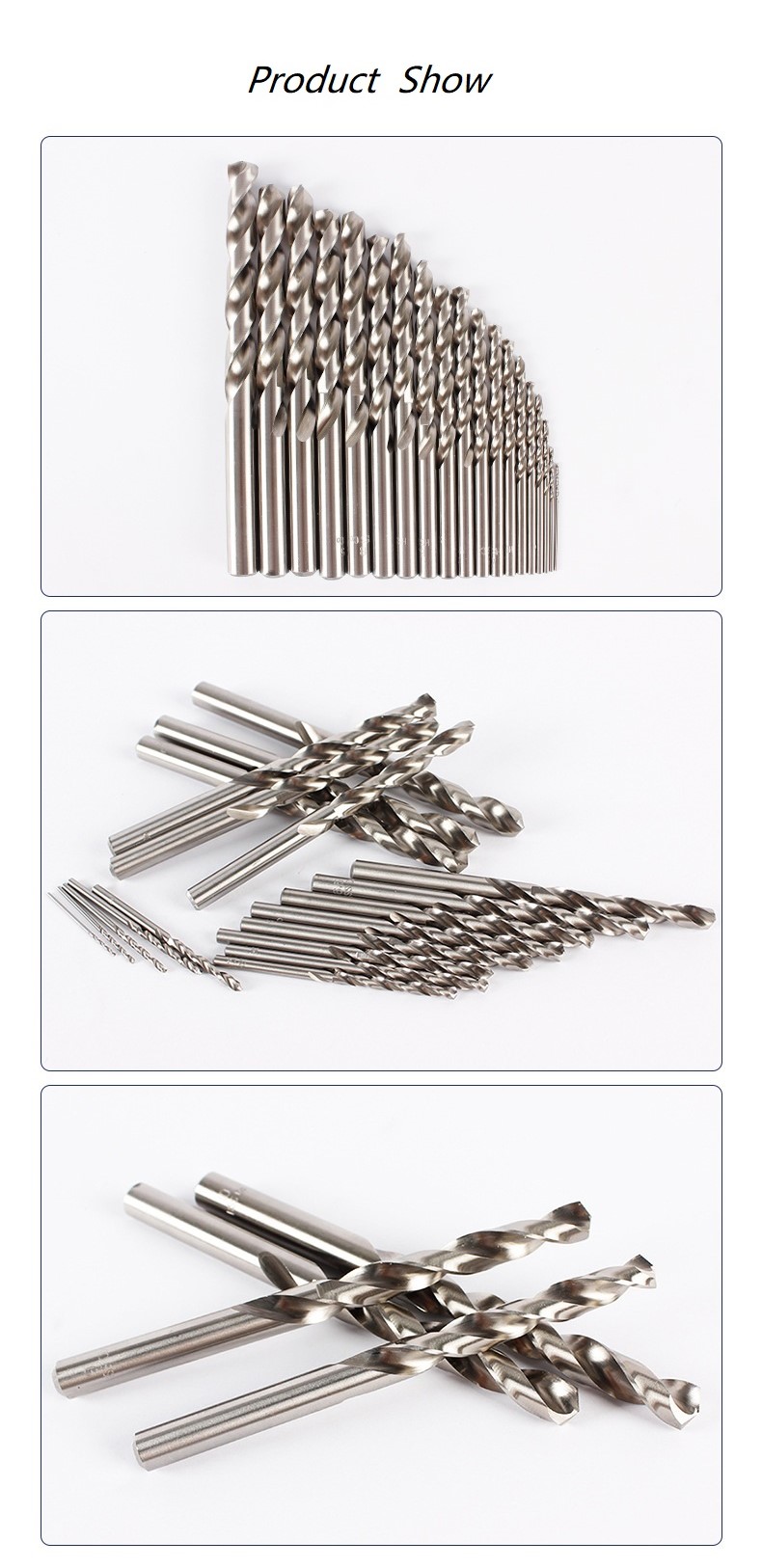

PRODUKT Show

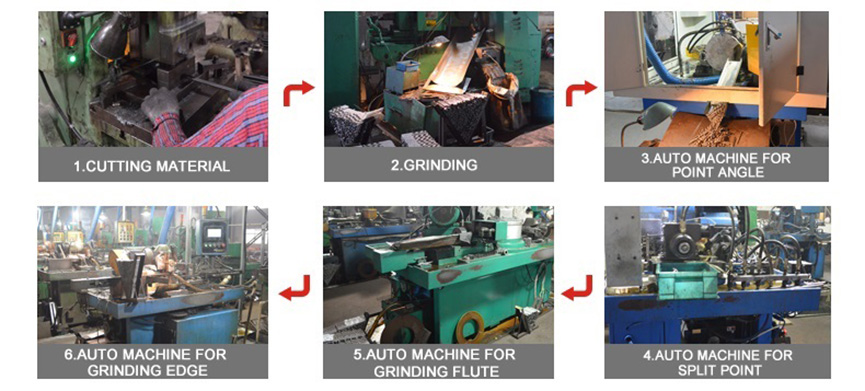

PROZESSFLOSS

Virdeeler

DIN338 voll geschliffen HSS M2 Spiralbuerer bidden eng Rei Virdeeler, dorënner:

Héich Haltbarkeet: HSS M2 Material bitt iwwerleeën Häert a Verschleißbeständegkeet fir eng laang dauerhaft Haltbarkeet, besonnesch beim Bueren duerch haart Materialien wéi Edelstol, Legierungsstol an Nichteisenmetaller.

Präzisioun a Genauegkeet: Voll geschliffen Rillen a Schneidkanten garantéieren eng präzis a konsequent Buerleistung a produzéiere propper, präzis Lächer.

Effizient Spanentfernung: Präzisiounsgeschliffen Nuten a Schneidkanten erliichteren eng effizient Spanentfernung, miniméieren d'Verstoppung an erhéijen d'Buereffizienz.

Erhéicht Buergeschwindegkeet: Den 135-Grad-Split-Point-Design miniméiert de Besoin fir Virbuerung, wat méi séier Bueren an eng erhéicht Produktivitéit erméiglecht.

REDUZÉIERT HËTZ A REIBUNG: Schnellstahlmaterial a Präzisiounsschleifen hëllefen d'Hëtzopbau an d'Reibung beim Bueren ze reduzéieren, wat zu engem méi rouegen Operatioun an enger méi laanger Liewensdauer vum Tool féiert.

Korrosiounsbeständegkeet: Déi glänzend Uewerfläch vum Buer ass korrosiounsbeständeg, wat d'Liewensdauer vum Buer verlängert an seng Schnëttleistung erhält. Villfältegkeet: Dës Buer si fir eng Villfalt vu Buerapplikatiounen gëeegent, wat se villfälteg a praktesch fir d'Benotzung an enger Villfalt vu Materialien an Industrien mécht.

Duerch dës Virdeeler bitt den DIN338 vollgeschliffenen HSS M2 Spiralbuer Zouverlässegkeet, Effizienz a Langlebigkeit bei Bueraarbechten.

| DIN338 HSS Spiralbuer | ||||||||

| Duerchmiesser (mm) | Flüttlängt (mm) | Gesamtlängt (mm) | Duerchmiesser (mm) | Flüttlängt (mm) | Gesamtlängt (mm) | Duerchmiesser (mm) | Flüttlängt (mm) | Gesamtlängt (mm) |

| 0,2 | 2,5 | 19.0 | 5.6 | 57,0 | 93,0 | 11.0 | 94,0 | 142,0 |

| 0,3 | 3.0 | 19.0 | 5.7 | 57,0 | 93,0 | 11.1 | 94,0 | 142,0 |

| 0,4 | 5.0 | 20.0 | 5.8 | 57,0 | 93,0 | 11.2 | 94,0 | 142,0 |

| 0,5 | 6.0 | 22.0 | 5.9 | 57,0 | 93,0 | 11.3 | 94,0 | 142,0 |

| 0,6 | 7.0 | 24.0 | 6.0 | 57,0 | 93,0 | 11.4 | 94,0 | 142,0 |

| 0,7 | 9.0 | 28.0 | 6.1 | 63,0 | 101.0 | 11,5 | 94,0 | 142,0 |

| 0,8 | 10.0 | 30.0 | 6.2 | 63,0 | 101.0 | 11.6 | 94,0 | 142,0 |

| 0,9 | 11.0 | 32,0 | 6.3 | 63,0 | 101.0 | 11.7 | 94,0 | 142,0 |

| 1.0 | 12.0 | 34,0 | 6.4 | 63,0 | 101.0 | 11.8 | 94,0 | 142,0 |

| 1.1 | 14.0 | 36,0 | 6.5 | 63,0 | 101.0 | 11.9 | 101.0 | 151.0 |

| 1.2 | 16.0 | 38,0 | 6.6 | 63,0 | 101.0 | 12.0 | 101.0 | 151.0 |

| 1.3 | 16.0 | 38,0 | 6.7 | 63,0 | 101.0 | 12.1 | 101.0 | 151.0 |

| 1.4 | 18.0 | 40,0 | 6.8 | 69,0 | 109.0 | 12.2 | 101.0 | 151.0 |

| 1.5 | 18.0 | 40,0 | 6.9 | 69,0 | 109.0 | 12.3 | 101.0 | 151.0 |

| 1.6 | 20.0 | 43,0 | 7.0 | 69,0 | 109.0 | 12.4 | 101.0 | 151.0 |

| 1.7 | 20.0 | 43,0 | 7.1 | 69,0 | 109.0 | 12,5 | 101.0 | 151.0 |

| 1.8 | 22.0 | 46,0 | 7.2 | 69,0 | 109.0 | 12.6 | 101.0 | 151.0 |

| 1.9 | 22.0 | 46,0 | 7.3 | 69,0 | 109.0 | 12.7 | 101.0 | 151.0 |

| 2.0 | 24.0 | 49,0 | 7.4 | 69,0 | 109.0 | 12.8 | 101.0 | 151.0 |

| 2.1 | 24.0 | 49,0 | 7,5 | 69,0 | 109.0 | 12.9 | 101.0 | 151.0 |

| 2.2 | 27.0 | 53,0 | 7.6 | 75,0 | 117.0 | 13.0 | 101.0 | 151.0 |

| 2.3 | 27.0 | 53,0 | 7.7 | 75,0 | 117.0 | 13.1 | 101.0 | 151.0 |

| 2.4 | 30.0 | 57,0 | 7.8 | 75,0 | 117.0 | 13.2 | 101.0 | 151.0 |

| 2,5 | 30.0 | 57,0 | 7.9 | 75,0 | 117.0 | 13.3 | 108.0 | 160,0 |

| 2.6 | 30.0 | 57,0 | 8.0 | 75,0 | 117.0 | 13.4 | 108.0 | 160,0 |

| 2.7 | 33,0 | 61,0 | 8.1 | 75,0 | 117.0 | 13,5 | 108.0 | 160,0 |

| 2.8 | 33,0 | 61,0 | 8.2 | 75,0 | 117.0 | 13.6 | 108.0 | 160,0 |

| 2.9 | 33,0 | 61,0 | 8.3 | 75,0 | 117.0 | 13.7 | 108.0 | 160,0 |

| 3.0 | 33,0 | 61,0 | 8.4 | 75,0 | 117.0 | 13.8 | 108.0 | 160,0 |

| 3.1 | 36,0 | 65,0 | 8,5 | 75,0 | 117.0 | 13.9 | 108.0 | 160,0 |

| 3.2 | 36,0 | 65,0 | 8.6 | 81.0 | 125,0 | 14.0 | 108.0 | 160,0 |

| 3.3 | 36,0 | 65,0 | 8.7 | 81.0 | 125,0 | 14.3 | 114.0 | 169,0 |

| 3.4 | 39,0 | 70,0 | 8.8 | 81.0 | 125,0 | 14,5 | 114.0 | 169,0 |

| 3.5 | 39,0 | 70,0 | 8.9 | 81.0 | 125,0 | 14.8 | 114.0 | 169,0 |

| 3.6 | 39,0 | 70,0 | 9.0 | 81.0 | 125,0 | 15.0 | 114.0 | 169,0 |

| 3.7 | 39,0 | 70,0 | 9.1 | 81.0 | 125,0 | 15.3 | 120.0 | 178,0 |

| 3.8 | 43,0 | 75,0 | 9.2 | 81.0 | 125,0 | 15,5 | 120.0 | 178,0 |

| 3.9 | 43,0 | 75,0 | 9.3 | 81.0 | 125,0 | 15.8 | 120.0 | 178,0 |

| 4.0 | 43,0 | 75,0 | 9.4 | 81.0 | 125,0 | 16.0 | 120.0 | 178,0 |

| 4.1 | 43,0 | 75,0 | 9,5 | 81.0 | 125,0 | 16.3 | 125,0 | 184,0 |

| 4.2 | 43,0 | 75,0 | 9.6 | 87,0 | 133,0 | 16,5 | 125,0 | 184,0 |

| 4.3 | 47,0 | 80,0 | 9.7 | 87,0 | 133,0 | 16,8 | 125,0 | 184,0 |

| 4.4 | 47,0 | 80,0 | 9.8 | 87,0 | 133,0 | 17.0 | 125,0 | 184,0 |

| 4.5 | 47,0 | 80,0 | 9.9 | 87,0 | 133,0 | 17.3 | 130,0 | 191.0 |

| 4.6 | 47,0 | 80,0 | 10.0 | 87,0 | 133,0 | 17,5 | 130,0 | 191.0 |

| 4.7 | 47,0 | 80,0 | 10.1 | 87,0 | 133,0 | 17,8 | 130,0 | 191.0 |

| 4.8 | 52,0 | 86,0 | 10.2 | 87,0 | 133,0 | 18.0 | 130,0 | 191.0 |

| 4.9 | 52,0 | 86,0 | 10.3 | 87,0 | 133,0 | 18,5 | 135,0 | 198.0 |

| 5.0 | 52,0 | 86,0 | 10.4 | 87,0 | 133,0 | 18,8 | 135,0 | 198.0 |

| 5.1 | 52,0 | 86,0 | 10.5 | 87,0 | 133,0 | 19.0 | 135,0 | 198.0 |

| 5.2 | 52,0 | 86,0 | 10.6 | 87,0 | 133,0 | 19.3 | 140,0 | 205.0 |

| 5.3 | 52,0 | 86,0 | 10.7 | 94,0 | 142,0 | 19,5 | 140,0 | 205.0 |

| 5.4 | 57,0 | 93,0 | 10.8 | 94,0 | 142,0 | 19.8 | 140,0 | 205.0 |

| 5.5 | 57,0 | 93,0 | 10.9 | 94,0 | 142,0 | 20.0 | 140,0 | 205.0 |